Oil Water Separators

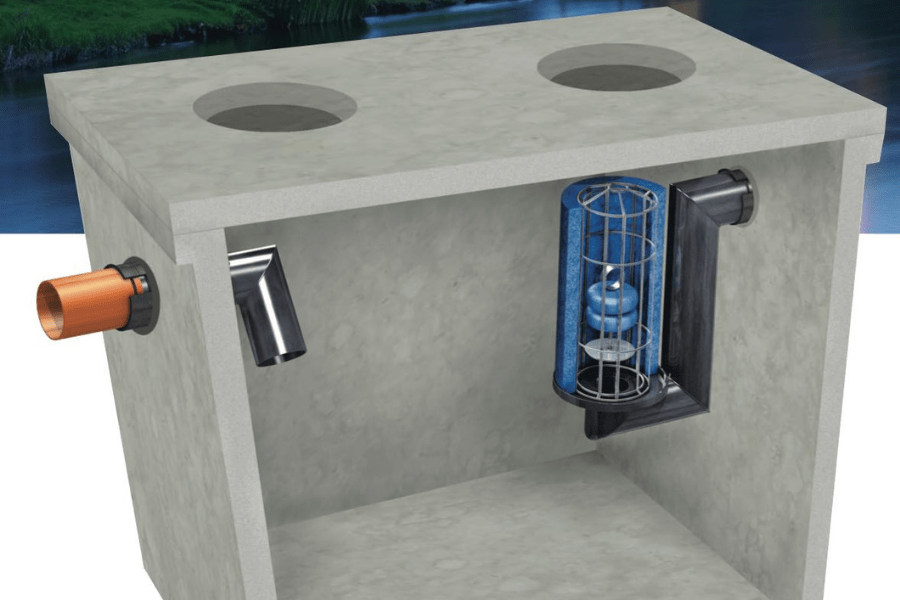

O’Reilly Oakstown’s high-efficiency coalescence oil water separators are fitted to surface water drainage systems to protect the environment from oil pollution.

Oakstown oil water separators conform to the European standard EN 858 for the design and use of prefabricated oil separators.

All separators fulfil European standards achieving results of oil removal much lower than 5 mg/L.